Alfa Laval AC30EQ / ACH30EQ

July 1, 2025

Alfa Laval AC220EQ / ACH220EQ

July 1, 2025Alfa Laval AC70X / ACH70X

Introduction

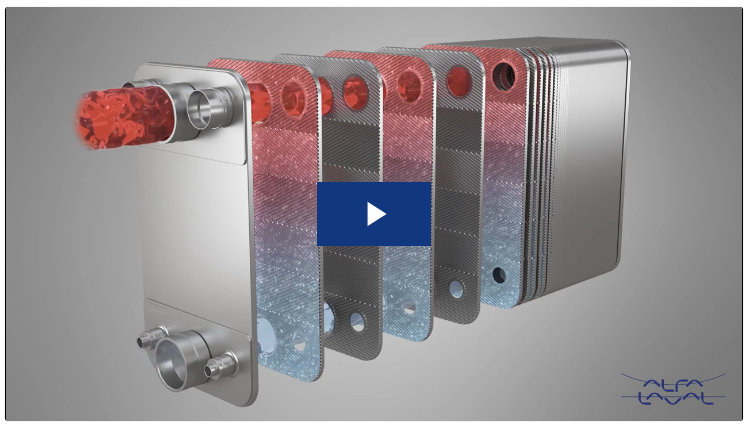

Alfa Laval AC brazed plate heat exchangers provide efficient heat transfer with a small footprint. They are specifically designed to work in air conditioning and refrigeration as evaporators and condensers in chillers and heat pumps.

Alfa Laval introduced its first brazed plate heat exchanger in 1977 and has since continuously developed and optimized its performance and reliability

Brazing the stainless steel plates together eliminates the need for gaskets and thick frame plates, which makes the heat exchanger compact and saves material. The brazing material seals and holds the plates together at the contact points ensuring optimal heat transfer efficiency and pressure resistance. Using advanced design technologies and extensive verification guarantees the highest performance and longest possible service lifetime.

The AlfaChill (AC) brazed plate heat exchangers are specifically designed for heat transfer in air conditioning, refrigeration and heat pump applications.

Innovative features for this single circuit heat exchanger include a patented distributor integrated in the plate design.

Typical applications

- Evaporator and condenser in chillers and heat pumps

- Economizer in chillers and heat pumps

The standard design supports a wide variety of HFC refrigerants such as R407C, R404A, R507, R134a. The high-pressure version is suitable for R410A and natural refrigerants (CO2 – propane).

Capacity range

AC70X/ACH70X cover capacities from 10 up to 80 kW for chillers and 5 kW to 40 kW for heat pumps. Based on standard components and a modular concept, each unit is custom-designed for each specific installation.

Request for quotation

To receive a quotation for brazed plate heat exchangers that meet your requirements, please provide Alfa Laval

representatives with:

– Required flow rates or heat load

– Temperature program (inlet and outlet

– Brine and refrigerant type

– Desired working pressure

– Maximum permitted water/brine pressure drop

– Connection types

Unique features to boost your performance

With more than 80 years of experience in heat transfer innovation, Alfa Laval knows what it takes to deliver high-performance solutions for any application. Our experts continuously develop new innovations that give our AC line of brazed plate heat exchangers more reliable and efficient performance.

DynaStatic

Flexible refrigerant distribution

PressureSecure

Unparalleled strength for demanding duties

FlexFlow

Superior thermal performance

IceSafe

Controlled, non-destructive freezing

REFuture

A future-proof investment for tomorrow’s refrigerants

Alfa Laval gas-to-liquid heat exchangers use thin, corrugated stainless steel plates to provide heat transfer from one medium to the other. Copper brazing seals the media in the plate pack, resulting in a high-efficiency heat exchanger that consists solely of surfaces that actively contribute to heat transfer. Contact points between the plates are also brazed, which improves resistance to pressure and temperature fatigue.

The arrangement of the channels formed between the plates ensures that media flow through alternate channels in a countercurrent pattern, which further optimizes the efficiency of the heat transfer. One channel is far larger than the other channel, enabling the unit to handle very large volumetric flow rates.

Contact Us

Do you have questions about our portfolio of brazed and fusion bonded plate heat exchangers? We can work with you to find the optimal model to fit your specific needs.